Good morning;

Like so many things, there must be a reason for this group's very existence.

I can offer the following: Now it does seem that we cannot buy anything which does not have some electronic components in it, or even a full blown microprocessor which is monitoring and adjusting the operation of the thing we have purchased. A very prominent example of this is the nature of the automobiles we can buy today. There are so many electronics systems in our cars now that we can safely say that we no longer take our cars to a mechanic for some work to be done. Now we must find an electronics technician with mechanical aptitude to work on our cars.

This same philosophy also applies to our cameras. Unless we are buying something made in the 1960s or earlier, that camera will have some sort of electronic system in it, from a built-in light meter to systems that take the light that it sees through the lens and chooses the lens opening and the shutter speed that it believes will work with that scene, assuming that it has an 18% average reflectance. Now we can over-ride the control system and at least tell it to shift the exposure up or down two or three stops when we feel that the scene is not a standard 18% reflectance.

Also with the cameras come the lenses. Even with the lenses we first started to see with Automatic Focusing capability back in the 1980s, it was noticed at that time that those early AF systems were both faster and more accurate than experienced photographers, under most situations. Yes, there were then, and there still are, many circumstances when you will want to go to a manual focusing mode to get the focus on what you want, or even to get the system to focus at all when you have a scene without any reasonable contrast parts where the focusing system can work. But still, most of the time they really do work.

Then we can look also at our enlarger timers and other systems that make our work with a camera and film much easier than it was back in the 1960s and earlier.

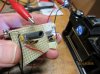

So, whether we are building something for our photography, or just trying to repair and maintain the systems we have bought, knowing how to work on electrical and electronic systems and how to use a soldering iron to work with "electrical glue," also known as solder, whether it is the older tin-lead (Sn-Pb) solder or one of the newer RoHS (Removal of Hazardous Substances) compliant solders, if we are going to work on them, we need to know how to do that.

I have been working with tin-lead solder with rosin flux for over 50 years now. The training received in this realm goes up to the NASA Reliable Electrical Connections School at the George C. Marshall Space Flight Center in Huntsville, Alabama. This is something that you can do and do it safely. There are a couple of things to observe, yes, and there is also the precaution that you cannot use a soldering iron that has been used with tin-lead solder on an RoHS solder constructed circuit. If you do and you use the standard RoHS solder with that tin-lead solder contaminated soldering iron tip, the RoHS solder will not flow properly. It will usually ball up and not make the electrical joint you are trying to achieve. The only real cure is to have two completely separate soldering iron systems; one for the older tin-lead solder and circuits, and another one for RoHS compliant solder and RoHS constructed circuits. DO NOT MIX THE TWO. If you do use an RoHS soldering iron on a tin-lead built circuit or mistakenly with tin-lead solder, that soldering iron now has just been converted to use on tin-lead circuitry only. It cannot be cleaned to make it work again with RoHS circuitry and solder. RoHS irons on only RoHS circuits.

OK. The RoHS topic is still something of controversy, and, yes, it did come out of legislation, and there are some problems with it. These things and the history are something that may be topics of discussion.

Welcome to a new group that is about something that is affecting us today.

Enjoy;

Ralph

Latte Land, Washington

Like so many things, there must be a reason for this group's very existence.

I can offer the following: Now it does seem that we cannot buy anything which does not have some electronic components in it, or even a full blown microprocessor which is monitoring and adjusting the operation of the thing we have purchased. A very prominent example of this is the nature of the automobiles we can buy today. There are so many electronics systems in our cars now that we can safely say that we no longer take our cars to a mechanic for some work to be done. Now we must find an electronics technician with mechanical aptitude to work on our cars.

This same philosophy also applies to our cameras. Unless we are buying something made in the 1960s or earlier, that camera will have some sort of electronic system in it, from a built-in light meter to systems that take the light that it sees through the lens and chooses the lens opening and the shutter speed that it believes will work with that scene, assuming that it has an 18% average reflectance. Now we can over-ride the control system and at least tell it to shift the exposure up or down two or three stops when we feel that the scene is not a standard 18% reflectance.

Also with the cameras come the lenses. Even with the lenses we first started to see with Automatic Focusing capability back in the 1980s, it was noticed at that time that those early AF systems were both faster and more accurate than experienced photographers, under most situations. Yes, there were then, and there still are, many circumstances when you will want to go to a manual focusing mode to get the focus on what you want, or even to get the system to focus at all when you have a scene without any reasonable contrast parts where the focusing system can work. But still, most of the time they really do work.

Then we can look also at our enlarger timers and other systems that make our work with a camera and film much easier than it was back in the 1960s and earlier.

So, whether we are building something for our photography, or just trying to repair and maintain the systems we have bought, knowing how to work on electrical and electronic systems and how to use a soldering iron to work with "electrical glue," also known as solder, whether it is the older tin-lead (Sn-Pb) solder or one of the newer RoHS (Removal of Hazardous Substances) compliant solders, if we are going to work on them, we need to know how to do that.

I have been working with tin-lead solder with rosin flux for over 50 years now. The training received in this realm goes up to the NASA Reliable Electrical Connections School at the George C. Marshall Space Flight Center in Huntsville, Alabama. This is something that you can do and do it safely. There are a couple of things to observe, yes, and there is also the precaution that you cannot use a soldering iron that has been used with tin-lead solder on an RoHS solder constructed circuit. If you do and you use the standard RoHS solder with that tin-lead solder contaminated soldering iron tip, the RoHS solder will not flow properly. It will usually ball up and not make the electrical joint you are trying to achieve. The only real cure is to have two completely separate soldering iron systems; one for the older tin-lead solder and circuits, and another one for RoHS compliant solder and RoHS constructed circuits. DO NOT MIX THE TWO. If you do use an RoHS soldering iron on a tin-lead built circuit or mistakenly with tin-lead solder, that soldering iron now has just been converted to use on tin-lead circuitry only. It cannot be cleaned to make it work again with RoHS circuitry and solder. RoHS irons on only RoHS circuits.

OK. The RoHS topic is still something of controversy, and, yes, it did come out of legislation, and there are some problems with it. These things and the history are something that may be topics of discussion.

Welcome to a new group that is about something that is affecting us today.

Enjoy;

Ralph

Latte Land, Washington