I find that very hard to believe indeed. VC paper is indeed sensitive to blue & green light and this sensitivity undoubtedly stretches deep into UV territory because that's where the innate sensitivity of silver halides lies anyway. But this UV-sensitivity is NOT a design criterion in enlarging papers, which you can very easily understand if you keep in mind that enlarger light sources for the majority of photographic history have been incandescent bulbs with a marginal/negligible UV component to their spectrum. The UV-transmission properties of enlarging lenses is just as much a technical 'bycatch' as the UV sensitivity of enlarging papers. It's not there on purpose, because it serves no practical function - it's just there because it's not worthwhile to remove it.Almost all enlarging lenses transmit quite some UV-A, because black and white paper is sensitive to UV-A to green light. It was a design consideration. I suspect that enlarging lenses for black and white (so not APO lenses for colour) where corrected to focus UV-A to green light in the same plane.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making an UV enlarger

-

A

- Thread starter Uncle Goose

- Start date

Recent Classifieds

-

For Sale Kodak's 1947 Sensitometric Step Table

- Started by Gaston 012

-

For Sale Photronix Mod 73 Transmission densitometer with instructions

- Started by Gaston 012

-

For Sale Eseco and XRite densitometers

- Started by gmikol

-

For Sale Speedotron 202 VF Flash Head and accessories

- Started by spoolman

-

Want to Buy Sekonic L208

- Started by RoboRepublic

Forum statistics

alanbradford

Subscriber

UV Enlarger project

A bit of a long post, already posted to Alt Photography group on FB - but this has been a long project and I feel sure some of you will be very interested in the details as much discussion has taken place here.

I finally have a prototype UV enlarger head, that is very powerful. I have now built the head and attached it to my IFF Ampliator chassis, the photos below show the construction. It is not yet ready for prime time and a Phase two is starting to deal with some issue I will describe below.

What I am trying to achieve is a projection of a small negative to print a larger Alt Photo print, for me using Salt or Platinum printing, without the need for enlarged internegatives or Digital Negatives and contact printing.

This was designed to use the IFF chassis and allow initially a 6x9 negative to be in the light path.

I had hoped to add more 500W LED’s to cover a larger negative, hence the over specified 1800W heatsink.

The main, and big problem I have is with the forward IR heat from the 500W UV 365nm LED COB - The IR heat is immense and burns the negatives in 45+ seconds

The reverse heat is well catered for with the 1800W heatsink and fans, so no issues overheating the LED COB, but way too much forward heat exists.

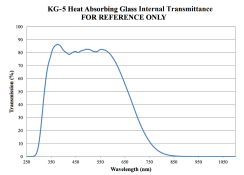

I have tried to filter that IR light with some exceptionally expensive Schott KG5 short pass filter glass that their data sheet shows, allows 85% UV at 365nm and should block IR above 780nm,

This did not seem to work at all – Schott do say that the behaviour will change in the presence of intense UV, clearly what I have!

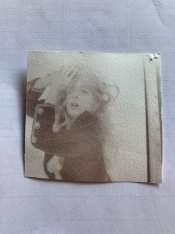

The negative shown here was exposed for 60 seconds before I smelt something....– Not happy!!~

Normally the Alternative Salt printing photographic process I use requires a same size negative as the final image and is contact printed under a 600W UV metal halide lamp driven from a ballast - At 50cm above the contact of negative/paper a good exposure takes 7 minutes.

The photo below was contact printed in the negative carrier, 25mm below the KG5 filter, 50mm below the 500W LED for only 5 seconds!!!! Yes, 5 seconds, same sort of exposure as you would get for normal Silver papers, showing just how much UV I have here. Exposure is somewhat OK at that time/intensity.

I simply have too much UV, too close to the negative carrier and will now try to move the UV LED so it is maybe 200mm above the negative and keep the KG5 just above the negative so 175mm below the LED

In the current prototype, a piece of Salt sensitised paper was put in the negative carrier for 60 seconds – It was burnt and smoking at that point – See the two small photos – Very bronzed on the sensitised side from huge overexposure and burnt on the back

The last photo was contact printed on the enlarger baseboard using the enlarger as the light path and for 10 minutes exposure – It is about 45%-50% underexposed, so 20 minutes would be about right. This is a fine time for me if I can overcome the destructive heat problems.

The lens used is an old 105mm Nikkor f5.6 that is know for excellent UV performance allowing 80%+ UV to pass - Normally the lens elements and each cement layer block UV and the combined result of a cemented 6 element lens is not much UV gets through. This has for now meant I do not need to go to dedicated Calcium Flouride and Silica UV lenses that are so expensive. I also tried an old Rodenstock 210mm lens and that too worked well - Seems the older lenses without coatings may be best for this.

I have been trying to focus the UV enlarger using a Peak focus finder with a WiFi telescope lens attached that displays to my i-Phone, but this is not so great. I think I will build in some white LED light for focusing and see just how close that is for the UV focus. No possibility of focussing the UV image by eye - The intense UV will blind you.

Not sure how to calculate what the difference may be between focus point on white light or UV? Anybody have an idea?

I will post updates to the group here as I make progress with Phase 2, but also happy to discuss directly.

Thanks to the many people whose brains I have picked along the way here, it is difficult to be SME on all elements of this work. I am based in Switzerland, but the IFF enlarger and prototype head are near Dijon, in France. Alan

A bit of a long post, already posted to Alt Photography group on FB - but this has been a long project and I feel sure some of you will be very interested in the details as much discussion has taken place here.

I finally have a prototype UV enlarger head, that is very powerful. I have now built the head and attached it to my IFF Ampliator chassis, the photos below show the construction. It is not yet ready for prime time and a Phase two is starting to deal with some issue I will describe below.

What I am trying to achieve is a projection of a small negative to print a larger Alt Photo print, for me using Salt or Platinum printing, without the need for enlarged internegatives or Digital Negatives and contact printing.

This was designed to use the IFF chassis and allow initially a 6x9 negative to be in the light path.

I had hoped to add more 500W LED’s to cover a larger negative, hence the over specified 1800W heatsink.

The main, and big problem I have is with the forward IR heat from the 500W UV 365nm LED COB - The IR heat is immense and burns the negatives in 45+ seconds

The reverse heat is well catered for with the 1800W heatsink and fans, so no issues overheating the LED COB, but way too much forward heat exists.

I have tried to filter that IR light with some exceptionally expensive Schott KG5 short pass filter glass that their data sheet shows, allows 85% UV at 365nm and should block IR above 780nm,

This did not seem to work at all – Schott do say that the behaviour will change in the presence of intense UV, clearly what I have!

The negative shown here was exposed for 60 seconds before I smelt something....– Not happy!!~

Normally the Alternative Salt printing photographic process I use requires a same size negative as the final image and is contact printed under a 600W UV metal halide lamp driven from a ballast - At 50cm above the contact of negative/paper a good exposure takes 7 minutes.

The photo below was contact printed in the negative carrier, 25mm below the KG5 filter, 50mm below the 500W LED for only 5 seconds!!!! Yes, 5 seconds, same sort of exposure as you would get for normal Silver papers, showing just how much UV I have here. Exposure is somewhat OK at that time/intensity.

I simply have too much UV, too close to the negative carrier and will now try to move the UV LED so it is maybe 200mm above the negative and keep the KG5 just above the negative so 175mm below the LED

In the current prototype, a piece of Salt sensitised paper was put in the negative carrier for 60 seconds – It was burnt and smoking at that point – See the two small photos – Very bronzed on the sensitised side from huge overexposure and burnt on the back

The last photo was contact printed on the enlarger baseboard using the enlarger as the light path and for 10 minutes exposure – It is about 45%-50% underexposed, so 20 minutes would be about right. This is a fine time for me if I can overcome the destructive heat problems.

The lens used is an old 105mm Nikkor f5.6 that is know for excellent UV performance allowing 80%+ UV to pass - Normally the lens elements and each cement layer block UV and the combined result of a cemented 6 element lens is not much UV gets through. This has for now meant I do not need to go to dedicated Calcium Flouride and Silica UV lenses that are so expensive. I also tried an old Rodenstock 210mm lens and that too worked well - Seems the older lenses without coatings may be best for this.

I have been trying to focus the UV enlarger using a Peak focus finder with a WiFi telescope lens attached that displays to my i-Phone, but this is not so great. I think I will build in some white LED light for focusing and see just how close that is for the UV focus. No possibility of focussing the UV image by eye - The intense UV will blind you.

Not sure how to calculate what the difference may be between focus point on white light or UV? Anybody have an idea?

I will post updates to the group here as I make progress with Phase 2, but also happy to discuss directly.

Thanks to the many people whose brains I have picked along the way here, it is difficult to be SME on all elements of this work. I am based in Switzerland, but the IFF enlarger and prototype head are near Dijon, in France. Alan

Attachments

alanbradford

Subscriber

Why do you say this, have you not followed the trails here? Internegatives are OK but you deal with dust and DigiNegs are a pain to get correct. The possibilities are today available as UV technology advances, and Internegative material is less and less available. Printing to A4 size from 6x6 cm Negatives is possible, and I am getting closer to a real easier solution. Look at the Video douwe uploaded. It is absolutely not a waste of time.

Unsurprisingly.I have tried to filter that IR light with some exceptionally expensive Schott KG5 short pass filter glass that their data sheet shows, allows 85% UV at 365nm and should block IR above 780nm,

This did not seem to work at all

What happens? The emitted heat from the LEDs heats up the glass, the glass radiates heat in return. It will slow the heating of the negative down a bit, but in the end it won't make much of a difference.

Besides, there is often this odd misconception that heat transfer in our daily environment is somehow dominated by IR transmission. This would be true if we lived in a vacuum. In reality, significant heat transfer will happen through plain old conduction - the air underneath your LED array heats up and transfers heat to other adjacent bodies.

The obvious solution then is to ensure sufficient airflow between the LED surface and the IR blocker. Yes, I'd keep that IR blocker in place, because also the radiated heat will likely be a problem at these power levels. So in your place, I'd suggest including a fan and an airduct to force cool air through the space between the LEDs and the IR filter.

Increasing the distance between the light source and other parts (IR blocker, negative) will probably help as well, but it's not entirely clear from your photos how you've solved it mechanically in this version.

As to the forced air cooling - I did the same in my first incarnation of the 100W color LED enlarger, which ran surprisingly cool. I didn't bother with the second version (ca. 365W full power) since it's not designed to run for extended periods of time anyway; focusing takes in the worst case scenario perhaps 1 minute. For Alt. process printing you need something that's thermally stable for 30+ minutes.

Everything except eating, drinking and procreating is a complete waste of time in a sense. Experimenting and innovating is what defines us as humans. Care to join us?Trying to make a UV enlarger light for alternative process techniques is a complete waste of time.

BJ68

Subscriber

UV Enlarger project

The main, and big problem I have is with the forward IR heat from the 500W UV 365nm LED COB - The IR heat is immense and burns the negatives in 45+ seconds

The reverse heat is well catered for with the 1800W heatsink and fans, so no issues overheating the LED COB, but way too much forward heat exists.

[...]

I have tried to filter that IR light with some exceptionally expensive Schott KG5 short pass filter glass that their data sheet shows, allows 85% UV at 365nm and should block IR above 780nm,

This did not seem to work at all – Schott do say that the behaviour will change in the presence of intense UV, clearly what I have!

The negative shown here was exposed for 60 seconds before I smelt something....– Not happy!!~

a) Which 500 W LED COB do you use? For my pictures https://www.photrio.com/forum/threads/uvivf-photography.185003/#post-2459153 I got the COBs from https://www.houkem.com.cn

Made 2 x a 100 W Unit see https://illumina-chemie.de/viewtopic.php?p=82160#p82160 and one 200 W Unit with 4 x 50 W UV COBs.

b) Forward IR-Heat-Problem:

Here at the University we have Fluorescence-Mikroskopes with "light guides" https://dymax.com/products/equipmen...-accessories/liquid-light-guides/light-guides

Perhaps a bigger one with a diameter like the COB-LED can be used as isolation....

Seems there is a way to cut IR out: https://www.newport.com/f/liquid-light-guides

Digging a little bit deeper in patents I found this: https://www.freepatentsonline.com/6418257.html in short a CaCl2 solution (in water) will transmit in the UVA range (320-400 nm). There ist mentioned a German patent DE000002406424A1 and in this you find that the addition of CoCl2 will reduce the transmission to UV and blue of the spectrum.

So my suggestion would be to take a cylinder made out of heat resistant plastic with two quartz or even normal glass disks wich is liquid tight and fill it mit CaCl2 solution and use that as IR filter. Expansion (through heating) and air bubble problems kann be solved with a tube which is connected and goes in an expansion vessel and to cool the things more down....you can circulate the liquid through a cooler.

I am here in Zürich at the University...if you want we can get in touch to look what possibilities there are to solve the heat problem....

bj68

alanbradford

Subscriber

Hi Bj68, This is the LED I used https://www.satisled.com/shop/produ...nm-410nm-420nm-led-12039?page=2&category=2330

I would be very interested to link up with you on this. Alan I am alan.aradford@bluewin.ch based in Neuchatel. Zurich no issues for me.

I would be very interested to link up with you on this. Alan I am alan.aradford@bluewin.ch based in Neuchatel. Zurich no issues for me.

TT1

Member

I'm actually quite surprised that the internet has so little information overall regarding "Making a UV enlarger," and basically no single, completed, successful attempt at building a functional UV enlarger for alt processes... Seems like the main problem is, more often not, forward heating. Still, even that problem sounds not that difficult a problem with some fan/ventilation-flush systems that could be incorporated much easier than the work that goes into this whole thing.

So the UV light also always emits IR?? If that's so, there's always going to be significant forward heating with any UV level that's enough to take a print, whatever happens in the lamp head??

I read that SMD is more efficient in terms of lumens/wattage, but COB is way smaller in the size of the light source's surface area, so my understanding is that the standard area of illumination is narrower with COB rather than wider (closer to a point source of light -although not entirely- in the scale of point source vs incandescent bulb) and you have the total amount of light focused brighter in a narrower area in the end. Is that why you went with COB? Ever tried the same or a similar setup with SMD LED UV with similar wattage? The few successful/functional setups I've seen online always used SMD. Do you think SMD vs COB could make any change between condenser vs diffusion systems in any respect, including but not limited to fundamental factors and parameters such as the forward heating problem and the exposure times because the total light from the source is directly narrowed down to a smaller area from the start? (I'm taking a leap of faith here and assuming the difference in the IR levels are negligibly small or the same between SMD & COB.)

500W sounds way too high not to burn the neg or the paper anyways? I've seen people try 10-20-30-50-100W LEDs (don't know if there's a conversion between SMD vs COB. ) Still, the imagination takes hold at times, so I was wondering if it could be possible to expose with much smaller exposure times with a way higher LED wattage. I presumed it would probably fail, but thanks for taking the fall for all of us who ever consider this...

So the UV light also always emits IR?? If that's so, there's always going to be significant forward heating with any UV level that's enough to take a print, whatever happens in the lamp head??

Why COB instead of SMD?The main, and big problem I have is with the forward IR heat from the 500W UV 365nm LED COB

I read that SMD is more efficient in terms of lumens/wattage, but COB is way smaller in the size of the light source's surface area, so my understanding is that the standard area of illumination is narrower with COB rather than wider (closer to a point source of light -although not entirely- in the scale of point source vs incandescent bulb) and you have the total amount of light focused brighter in a narrower area in the end. Is that why you went with COB? Ever tried the same or a similar setup with SMD LED UV with similar wattage? The few successful/functional setups I've seen online always used SMD. Do you think SMD vs COB could make any change between condenser vs diffusion systems in any respect, including but not limited to fundamental factors and parameters such as the forward heating problem and the exposure times because the total light from the source is directly narrowed down to a smaller area from the start? (I'm taking a leap of faith here and assuming the difference in the IR levels are negligibly small or the same between SMD & COB.)

500W sounds way too high not to burn the neg or the paper anyways? I've seen people try 10-20-30-50-100W LEDs (don't know if there's a conversion between SMD vs COB. ) Still, the imagination takes hold at times, so I was wondering if it could be possible to expose with much smaller exposure times with a way higher LED wattage. I presumed it would probably fail, but thanks for taking the fall for all of us who ever consider this...

I'm actually quite surprised that the internet has so little information overall regarding "Making a UV enlarger," and basically no single, completed, successful attempt at building a functional UV enlarger for alt processes... Seems like the main problem is, more often not, forward heating. Still, even that problem sounds not that difficult a problem with some fan/ventilation-flush systems that could be incorporated much easier than the work that goes into this whole thing.

Yes there is. Check douwe's enlarger. He has managed the heaat problem too.

alanbradford

Subscriber

douwe has used a very elegant point light source design, something like the last PLS Durst 1200. He has a custom LED made that gives a small UV source that is carefully "condensed" and is used to go inside the back surface of the lens he is using for final projection. No losses. As such he does not have to deal with the heat I have., all his is "in use" as I understand it. Some thing like the last Durst L

alanbradford

Subscriber

finger trouble, sorry.. Durst L 1200 Point light source enlargers. Smart idea, my "blast it and see 500W method" is more of an issue that I do see now in hind sight.

COB was chosen to not be an issue with not having sufficient UV, and to have so much UV so I could tone down going forward, I had not realised the disadvantages of this approach.

COB was chosen to not be an issue with not having sufficient UV, and to have so much UV so I could tone down going forward, I had not realised the disadvantages of this approach.

TT1

Member

So this will be mainly about the forward heating problem if you excuse my very bad level of knowledge in the field of physical material sciences as I'm figuring it out...

So if you use a UV-A LED (smd/cob/e27) with a fixed wavelength such as 380 or 395nm, do you still get significant forward heating from IR? Do these lamps, although advertised as emitting a certain UV-A wavelength, also always emit IR from the opposite end of the visible spectrum?

My understanding is there should be no IR rays emitted since the UV rays (and the visible purple rays) should be outside of the IR wavelength region?

Is the forward heating problem only because of IR? Will I get IR beams emitted from a LED chip even though I get a specific chip for a specific UV-A wavelength?

For example, with the 3d printer UV-A led chip douwe is using, do you get forward heating at all, especially when you go up to higher exposure times like several hours and days? (something like this, but varying wattage 10-50W: https://aliexpress.com/item/32965845170.html ) I thought the way he basically solved the forward heating problem for his setup is by decreasing exposure times to humane levels such as a couple of minutes...

I've also seen a 10W chip used with a slide projector lens -which also seems common- for several hours (even 1+ day) without a mention of any forward heating problem here:

Is this simply because he's using a low-wattage lamp? Would this setup have significant forward heating with, say, a 30 or 50W 395nm UV-A chip?

So if you use a UV-A LED (smd/cob/e27) with a fixed wavelength such as 380 or 395nm, do you still get significant forward heating from IR? Do these lamps, although advertised as emitting a certain UV-A wavelength, also always emit IR from the opposite end of the visible spectrum?

My understanding is there should be no IR rays emitted since the UV rays (and the visible purple rays) should be outside of the IR wavelength region?

Is the forward heating problem only because of IR? Will I get IR beams emitted from a LED chip even though I get a specific chip for a specific UV-A wavelength?

For example, with the 3d printer UV-A led chip douwe is using, do you get forward heating at all, especially when you go up to higher exposure times like several hours and days? (something like this, but varying wattage 10-50W: https://aliexpress.com/item/32965845170.html ) I thought the way he basically solved the forward heating problem for his setup is by decreasing exposure times to humane levels such as a couple of minutes...

I've also seen a 10W chip used with a slide projector lens -which also seems common- for several hours (even 1+ day) without a mention of any forward heating problem here:

Is this simply because he's using a low-wattage lamp? Would this setup have significant forward heating with, say, a 30 or 50W 395nm UV-A chip?

I think douwe's "secret" is good condensation and using the light efficiently. If you blast the light in diffused way towards the negative, most of the energy ends up as heat in the negative rather than in the correct part of the enlarger lens?

I talked with douwe on video about dust being problematic in his enlarger; that speaks about the quality of condensation of light rays in his machine.

I talked with douwe on video about dust being problematic in his enlarger; that speaks about the quality of condensation of light rays in his machine.

Probably a bit. Most of it will be plain old direct heat transfer though. COB led heats up, transfers heat to air around COB led, air transfers heat to other components.So if you use a UV-A LED (smd/cob/e27) with a fixed wavelength such as 380 or 395nm, do you still get significant forward heating from IR?

Part of the heat will also be emitted in the form of IR. Mostly very long-wave.

Err...well, in a perfect world, they wouldn't. In reality, if you take a 100W COB led, you can count yourself lucky if 60W or so are converted into heat and the rest becomes light.Do these lamps, although advertised as emitting a certain UV-A wavelength, also always emit IR from the opposite end of the visible spectrum?

And then of course the light is absorbed by whatever is hit by it and...is converted to heat.

In the end, out of the 100W of electrical power you dump into a COB led, virtually the entire100W will turn into heat inside the room the enlarger with the COB led is in.

In your attempt to understand all this, start with the 2nd law of thermodynamics. I'm sure you're actually familiar with it. It applies here as well!

alanbradford

Subscriber

Hi TT1, douwe has looked at exactly the full path and produced a source (his custom LED) and destination (inside diameter of enlarging lens) that eventually match, so no spare light is going astray, Essentially, just take the source light and pass all of it to the exit point using the condensers to efficiently "move" the light. So, unlike what I have done, there is not a mass of extra unused UV to heat the "wrong" elements. What seems essentially simple, to enlarge using UV, is not so if you (like me) dod not understand all the physics issues here. If you look at the main trails on the FB post I made, https://www.facebook.com/groups/AlternativePhotographicProcesses/?multi_permalinks=10158633427032749

you will see some very good information from people who have more experience in this area than I do. Lot's of good suggestions and explanations as to what is probably happening, ands what needs to be avoided.. Alan

you will see some very good information from people who have more experience in this area than I do. Lot's of good suggestions and explanations as to what is probably happening, ands what needs to be avoided.. Alan

alanbradford

Subscriber

Hi Bj68, This is the LED I used https://www.satisled.com/shop/produ...nm-410nm-420nm-led-12039?page=2&category=2330

I would be very interested to link up with you on this. Alan I am alan.aradford@bluewin.ch based in Neuchatel. Zurich no issues for me.

Hi Bj68, This is the LED I used https://www.satisled.com/shop/produ...nm-410nm-420nm-led-12039?page=2&category=2330

I would be very interested to link up with you on this. Alan I am alan.aradford@bluewin.ch based in Neuchatel. Zurich no issues for me.

Apologies - dumb typo - I am alan.bradford@bluewin.ch

cliveh

Subscriber

- Joined

- Oct 9, 2010

- Messages

- 7,484

- Format

- 35mm RF

Everything except eating, drinking and procreating is a complete waste of time in a sense. Experimenting and innovating is what defines us as humans. Care to join us?

No because you will not succeed. Prove me wrong!

alanbradford

Subscriber

Hi Clive, maybe I replied wrongly to my own post here, but it was not to you I was replying, but to Bj68, so apologies but I don't really understand what you are trying to say here. I am not here to prove you wrong or right, not sure why you need that. I am looking for positive assistance to a real problem I have and many are making helpful suggestions. If you have no technical suggestions it may be better to just drop out of the conversation, your views are fine and that is the nature of groups, but please don't condemn people for trying to make advances even if we are in your view misguided. Thanks, Alan

cliveh

Subscriber

- Joined

- Oct 9, 2010

- Messages

- 7,484

- Format

- 35mm RF

Hi Clive, maybe I replied wrongly to my own post here, but it was not to you I was replying, but to Bj68, so apologies but I don't really understand what you are trying to say here. I am not here to prove you wrong or right, not sure why you need that. I am looking for positive assistance to a real problem I have and many are making helpful suggestions. If you have no technical suggestions it may be better to just drop out of the conversation, your views are fine and that is the nature of groups, but please don't condemn people for trying to make advances even if we are in your view misguided. Thanks, Alan

Will do and wish you well.

I'm not playing this game. I'm just thinking along. Contrary to you, I'm willing to apply my brain to something I think has the possibility to succeed instead of throwing in the towel due to lack of awareness of the technology involved.No because you will not succeed.

Btw, concerning the 'proving you wrong part': semiconductor lithography machines have been around since the 1980s. They're essentially UV enlargers - with the exception that they are set up to reduce instead of enlarge, typically by a factor of 4. Doesn't matter though. Yes, they use lenses with materials such as CaF if memory serves instead of plain glass...but then again, they use 248nm instead of 360~400nm as we do in alt. process printing.

You've already been proven wrong...about 40 years ago. Your nay-saying demonstrates nothing but a lack of knowledge on your part.

BJ68

Subscriber

Found something::

Transmission Filters for the Ultraviolet

https://www.osapublishing.org/josa/fulltext.cfm?uri=josa-38-11-929

In short you can use a solution of such as Copper(II)sulfate to cut off IR:

[....]Cupric sulfate is the most useful general filter for removing the infra-red, when only the near ultraviolet and visible are to be isolated. Curve 3, Fig. 1, shows the transmission of a 5.0 cm path of a 100 g/l aqueous solution of CuSO4·5H2O. Its stability in intense mercury arc is good.[...]

And the nice thing is, you can pump the solution through the filter, so no heating problems....

bj68

Transmission Filters for the Ultraviolet

https://www.osapublishing.org/josa/fulltext.cfm?uri=josa-38-11-929

In short you can use a solution of such as Copper(II)sulfate to cut off IR:

[....]Cupric sulfate is the most useful general filter for removing the infra-red, when only the near ultraviolet and visible are to be isolated. Curve 3, Fig. 1, shows the transmission of a 5.0 cm path of a 100 g/l aqueous solution of CuSO4·5H2O. Its stability in intense mercury arc is good.[...]

And the nice thing is, you can pump the solution through the filter, so no heating problems....

bj68

I'd much rather deal with digitally enlarged negatives - no dust, you can deal with any contrast issues or mechanical flaws your original might have prior to printing, and once you learn how to do it properly, it's a very simple set of repetitive steps to make it. And if you're feeling lazy, you can just use curves other people have posted on the internet to skip a lot of the boring, repetitive steps that go into making a digital negative. Plus, if you damage the negative, you can just reprint it.Why do you say this, have you not followed the trails here? Internegatives are OK but you deal with dust and DigiNegs are a pain to get correct. The possibilities are today available as UV technology advances, and Internegative material is less and less available. Printing to A4 size from 6x6 cm Negatives is possible, and I am getting closer to a real easier solution. Look at the Video douwe uploaded. It is absolutely not a waste of time.

Having done the digital negative step several hundred times now as part of a project I'm working on, it's a superior technique. I don't want/need a UV lamphouse that is so powerful it can set my negatives on fire and/or blind me. For an investment of $200, I have an LED light source that covers 16x22 inches completely evenly, and produces a properly exposed Palladium print in 2 minutes. I can use it 24/7/365, in any weather.

I won't say the UV enlarger is a waste of time - there's always something to be learned by attempting, even (or especially) if it ends in abject failure, or does not produce a result that is immediately obvious as an improvement. But I would argue that a UV-based enlarger is, commercially anyway, a dead end, as it caters to an increasingly small audience of people who want to do things the really hard way.

Last edited:

More or less any kind of enlarger is a commercial dead end. It's all niches within niches, lots of R&D effort for tiny volumes and only 'sensible' if the combination of hobby and a small remuneration is feasible for someone.commercially anyway

I can imagine. Digital negatives are great - if you like that way of working. I personally didn't. The digital part and the inkjet step took the fun out of printing for me. I can imagine I'm not the only one - and that it would make the whole endeavor worthwhile. Yes, as a hobby/enthusiast exercise.'d much rather deal with digitally enlarged negatives

Sunlight is fine if you are a casual printer with these processes. Anything more than that and you need consistency and availability that sunlight can't provide.Trying to make a UV enlarger light for alternative process techniques is a complete waste of time. As others have said, make large inter-negs for contact printing in sunlight.

cliveh

Subscriber

- Joined

- Oct 9, 2010

- Messages

- 7,484

- Format

- 35mm RF

I'm not playing this game. I'm just thinking along. Contrary to you, I'm willing to apply my brain to something I think has the possibility to succeed instead of throwing in the towel due to lack of awareness of the technology involved.

Btw, concerning the 'proving you wrong part': semiconductor lithography machines have been around since the 1980s. They're essentially UV enlargers - with the exception that they are set up to reduce instead of enlarge, typically by a factor of 4. Doesn't matter though. Yes, they use lenses with materials such as CaF if memory serves instead of plain glass...but then again, they use 248nm instead of 360~400nm as we do in alt. process printing.

You've already been proven wrong...about 40 years ago. Your nay-saying demonstrates nothing but a lack of knowledge on your part.

I thought you were talking about a UV enlarger, not a reducer!

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |